Why Refabrication is so important for the Circular Economy

-

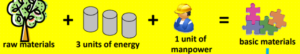

In industry, ¾ of the energy is used to produce inputs such as cement and steel, but only ¼ is used to produce finished products such as buildings or cars

-

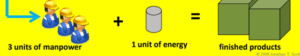

For the use of labor power, the relationship is the opposite: three quarters are used to produce finished products

(Stahel/Reday1976: The Potential for Substituting Manpower for Energy).

This is important as the energy and environmental costs of extracting new resources are typically large:

«Materials come with a multiple backpack of mining waste and environmental impairment. The backpacks of mining waste (measured in tonnes) differ for each material and are highest for rare metals such as gold (with a backpack of 500,000), lowest for plastics (with a backpack of 0.1).

Manufactured capital in the form of infrastructure, buildings, goods and components has individual accumulated backpacks of all the materials and energies they embed, which have to be calculated individually.»

Walter R. Stahel (2019:46) Circular Economy-A users guide.

Pressure on water resources, land areas, bio-diversity, conflicts and working conditions are further adding up the human and environmental costs.

Visualising the Energy-Labour relationships

Phase 1 in the production of new goods: Raw materials are converted into inputs (each unit represents 25% of the total need):

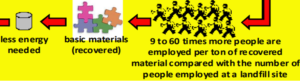

Energy/Labor ratio in Remanufacturing:

Based on Jonathan T. Scott (2011) [ed: Walter R. Stahel] : New Standards for Long-Term Business Survival

REFABRICATION requires much less raw materials and energy. This is because input goods are only needed to supplement what is lost in the remanufacturing process. And, remanufacturing of mass-produced goods costs about 40% less than corresponding new goods of the same quality. (Walter R. Stahel 2019:34: Circular Economy-A users guide)

This contributes to the rationale for the Industrialized Circular Economy:

By extending the life of products through reuse, repair, remanufacturing, technological upgrades and new uses, it uses labor instead of energy and local workshops instead of centralized factories. In this way, local job creation and the reindustrialisation of regions are facilitated.

(Own re-translation from the SINTEF-published Norwegian edition of Walter R. Stahel 2019: Circular Economy-A users guide (Sintef (2019:22) Sirkulærøkonomi – en håndbok,)